Regenerative medicine (RM) holds a promise, but it’s imperative to make this a reality as well and this can be challenging. Not only is the premise of RM very different from current medical practice, it also comes with specific challenges. RM often relies on a patient’s own tissue and cells. This means that the required supply chain is two-directional, and that it involves the transportation of fragile human tissue.

What is ICAT?

Innovation Center for Advanced Therapies (ICAT) aims to improve and accelerate the translation of research into healthcare or clinical solutions, by bringing together all relevant expertise and infrastructure for the development of regenerative treatments, Advanced Therapy Medicinal Products (ATMPs) and disease models using biofabrication and 3D bioprinting.

Joost van Duijn, business developer and project manager at ICAT, explains: ‘It’s really about setting up a translational workflow that connects preclinical research to patient care. Because in the end, that’s what we all strive for.’

It takes a village to raise an ATMP

The variety of disciplines needed for ATMP development is considerable. ‘It starts with both breadth and excellence in research,’ says Van Duijn, ‘and thanks to the strong cooperation between the University Medical Center Utrecht, the Veterinary and Science faculties of Utrecht University, Prinses Maxima Medical Center and the HU University of Applied Sciences Utrecht, we have plenty of that.’ But to bring this research to the clinic, input is needed to achieve production standards, certificates, regulation and profitability. ‘We all know Technology Readiness Level, but in fact, we are also talking about Clinical Readiness Level and Business Readiness Level. They all need to be considered for the product to be successful.’

Bringing together expertise

ICAT is unique in that it offers a place for excellence in research, but also clinical perspectives and collaborations with businesses. The center consists of three parts:

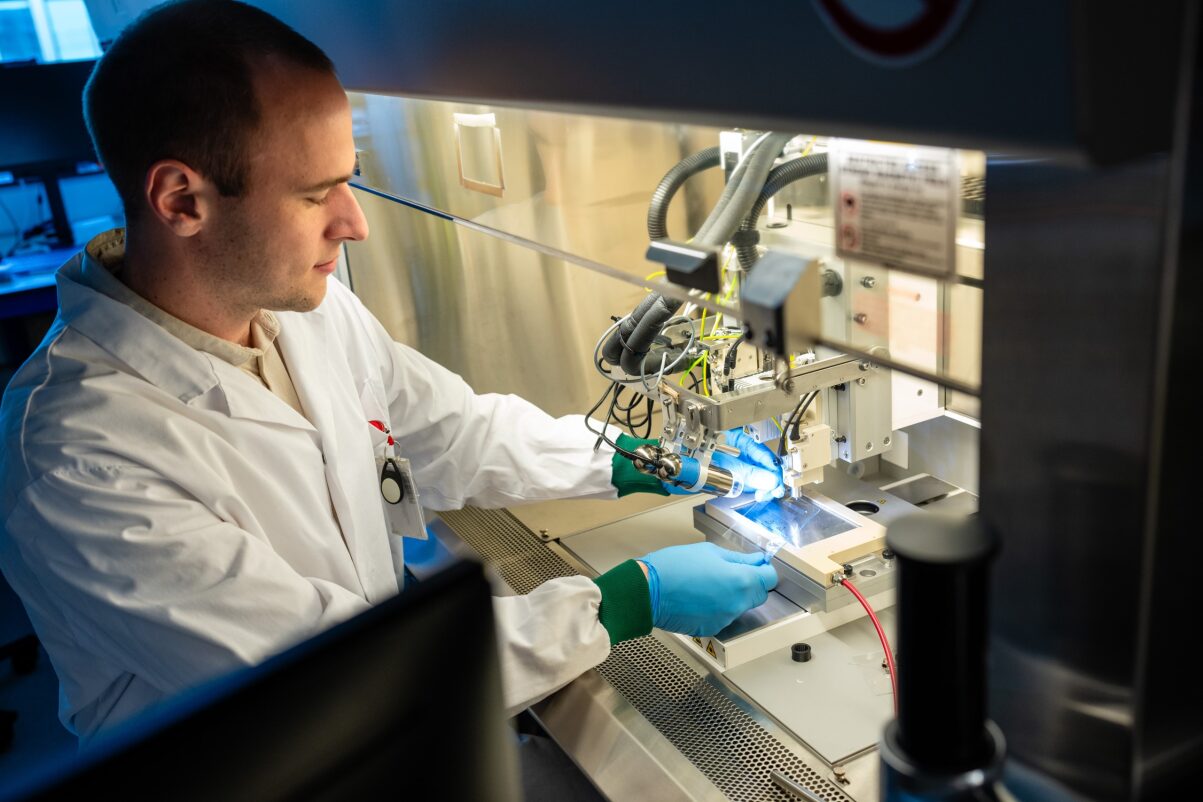

Biofabrication Pilot Facility. Organs and living tissues have very complex structures that cannot be reproduced well with existing technology. Biofabrication brings (engineered) cells and biomaterials together, for example with the aid of 3D bioprinting, in a natural or simulated environment to create functional 3D tissue. The aim of this biofabrication facility is to use patient’s own material and to implant it back into the patient after reprocessing. A second application is the validation, standardization, and automation of organ and patient-specific in vitro models to predict the effectiveness and safety of therapies in a specific patient or patient population.

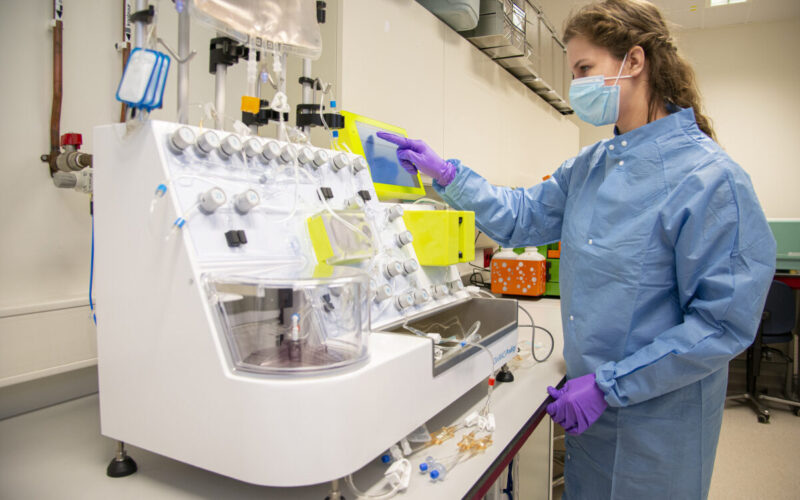

GMP Simulation Facility. In a GMP (Good Manufacturing Practice) simulation facility it is possible to efficiently develop, validate and optimize production protocols and to train employees, so that the development and scaling up of production technology and processes can be significantly accelerated and improved.

The Biofabrication pilot facility and the GMP Simulation Facility are located in Zeist, in a dedicated innovation facility offering dynamic coworking spaces and advanced life science laboratories. ‘Here, we offer two options for companies to join us,’ says Van Duijn. ‘They can enter a co-development trajectory in which we combine expertise and develop ATMPs together. Or they can start a membership on our facilities and services. This option is more interesting for spin-off companies, as we also offer coaching to get to market.’

GMP Production Facility. The availability of a GMP production facility with sufficient capacity is necessary to optimize the translation to the clinic and to continue to provide the patient with the best and most innovative care. The current Cell Therapy Facility at UMC Utrecht has four cleanrooms for the production of both stem cell therapies and ATMPs. This facility will be expanded to nine cleanrooms in order to meet the increasing demand for ATMPs in particular.

The GMP Production Facility for ATMP production is located in the UMC Utrecht, at the Cell Therapy Facility. Van Duijn: ‘This facility has extensive experience with the production license needed to produce ATMPs and regenerative therapies, either for clinical trials or under hospital exemption. And in addition to this valuable experience they are an educational center as well.’

So far, ICAT has played a role in the development of the IMPACT clinical trial, stem cell therapy for cartilage damage, the RegMed XB moonshots, and in the PACMAN study.

ICAT is part of RegMed XB

In 2016, Utrecht, Eindhoven, Leiden, Maastricht and Leuven (Belgium) initiated RegMedXB, which stands for Regenerative Medicine Crossing Borders. It is a collaboration of research institutions, governments, provinces, health funds and industrial partners aiming to develop therapies for chronic diseases, based on stem cells, mini-organs, tissues and smart (bio)materials. They are aiming to achieve four ‘moonshots’ – visionary projects that project a cure for diabetes, osteoarthritis, kidney disease or the regeneration of the human heart.

ICAT utilizes and catalyzes the Utrecht ecosystem

The Netherlands, and the Utrecht Science park (USP) in particular, is recognised as a leading centre for regenerative medicine innovation, translating research into new findings to improve patient health, reduce costly treatment and share knowledge. All in all, Utrecht has been steadily building a successful research cluster and boasts the largest number of RegMed researchers in the Netherlands, as well as the biggest multidisciplinary base.

This is due to the presence of leading companies, world-class research institutes and top-level academic establishments: University of Utrecht (UU), University Medical Center Utrecht (UMC Utrecht), Hubrecht Institute Princess Máxima Center for Pediatric Oncology and HU University of Applied Sciences Utrecht. The USP also boasts 8 SME’s and 3 start-ups that focus on RM. Having so many organisations within walking distance makes it easier to share research and expertise and develop solutions that can be applied directly to patients.

The unique Utrecht proposition in RM

Utrecht is the only academic centre in the Netherlands to offer a complete range of regenerative medicine education and training: two master’s programmes (Regenerative Medicine & Technology and Biofabrication 3D printing), a PhD programme in Regenerative Medicine, electives and summer schools.

In general, the Utrecht Region has consistently been ranked as one of Europe’s most competitive regions by the European Commission and is the hotspot of the Dutch healthcare industry – the Heart of Health. It’s also located in the middle of the Netherlands, an open, stable and accessible country, situated itself in the middle of Europe and renowned for its welcoming attitude to international companies.