Researchers at UMC Utrecht have developed an innovative 3D-printed mold that makes the treatment of nasal cancer more accurate and patient-friendly. Thanks to the customized mold, tumors can be irradiated more precisely. This results in less damage to surrounding tissue and a faster recovery.

Radiation is an effective cancer treatment, but the radiation often causes side effects because it passes through the body. This means that surrounding healthy tissue is exposed to unwanted radiation effects. This often causes side effects, especially in cases of cancer in the head and neck area, where practitioners have to deal with a lot of sensitive tissue near the tumor. Every year, 50 to 60 people are diagnosed with nasal cancer.

Radiation damage can be limited by using internal radiation. In this so-called brachytherapy, practitioners place the radioactive source in or as close as possible to the tumor via small tubes. The technique causes less damage to the surrounding tissue and is therefore used for tumors in the head and neck area whenever possible.

The technique works as follows: healthcare professionals make small holes in the nose close to the tumor, into which small tubes are inserted. These accommodate a cable with a radioactive source attached to it. A computer program determines which tube the cable runs through and how long the radioactive source remains in place. The treatment is complete when the desired amount of radiation has been delivered, usually after about five minutes. This is repeated once or twice a day for up to a week and a half.

The technique works well, but is often uncomfortable for the patient, says Mischa de Ridder, radiation oncologist at UMC Utrecht. “We always try to irradiate the tumor as effectively as possible with as little tissue damage as possible from the punctures. However, in addition to the radiation damage, the punctures can also cause damage to the nose.” Together with his colleagues, he has improved the therapy. They have designed a nose mold, which they 3D print to measure for each patient. This allows practitioners to place the tubes as precisely as possible, so they can achieve the same goal with fewer tubes.

“At UMC Utrecht, we are the only ones in the world to apply this technique. In the design, we make clever use of the natural cavities in the nose. As a result, we often only need to place one tube, whereas standard brachytherapy often requires dozens. This makes the treatment less stressful and more accurate.”

Research by De Ridder and his colleagues shows that the mold offers a better and more effective way to treat people with nasal cancer. “In almost everyone who underwent the treatment, the radiation reached the tumor very accurately, after which the tumor disappeared and the nose could be preserved.” The patients also experienced fewer side effects because the radiation was not directed at surrounding tissues and the practitioners had to make fewer holes in the nose.

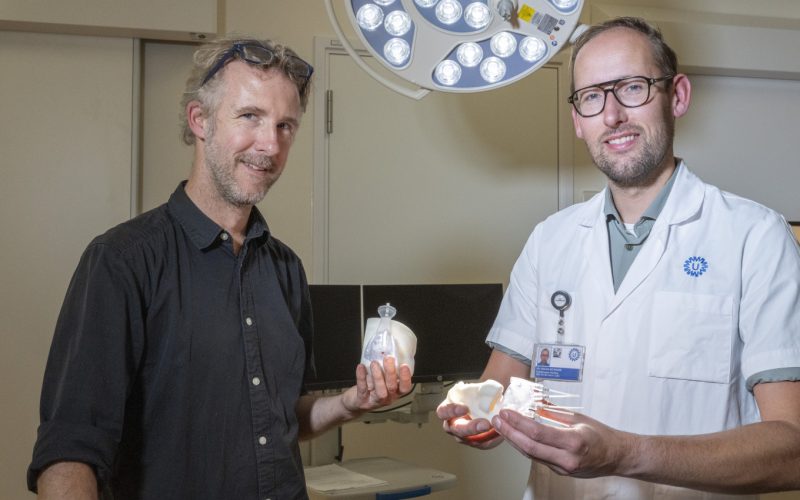

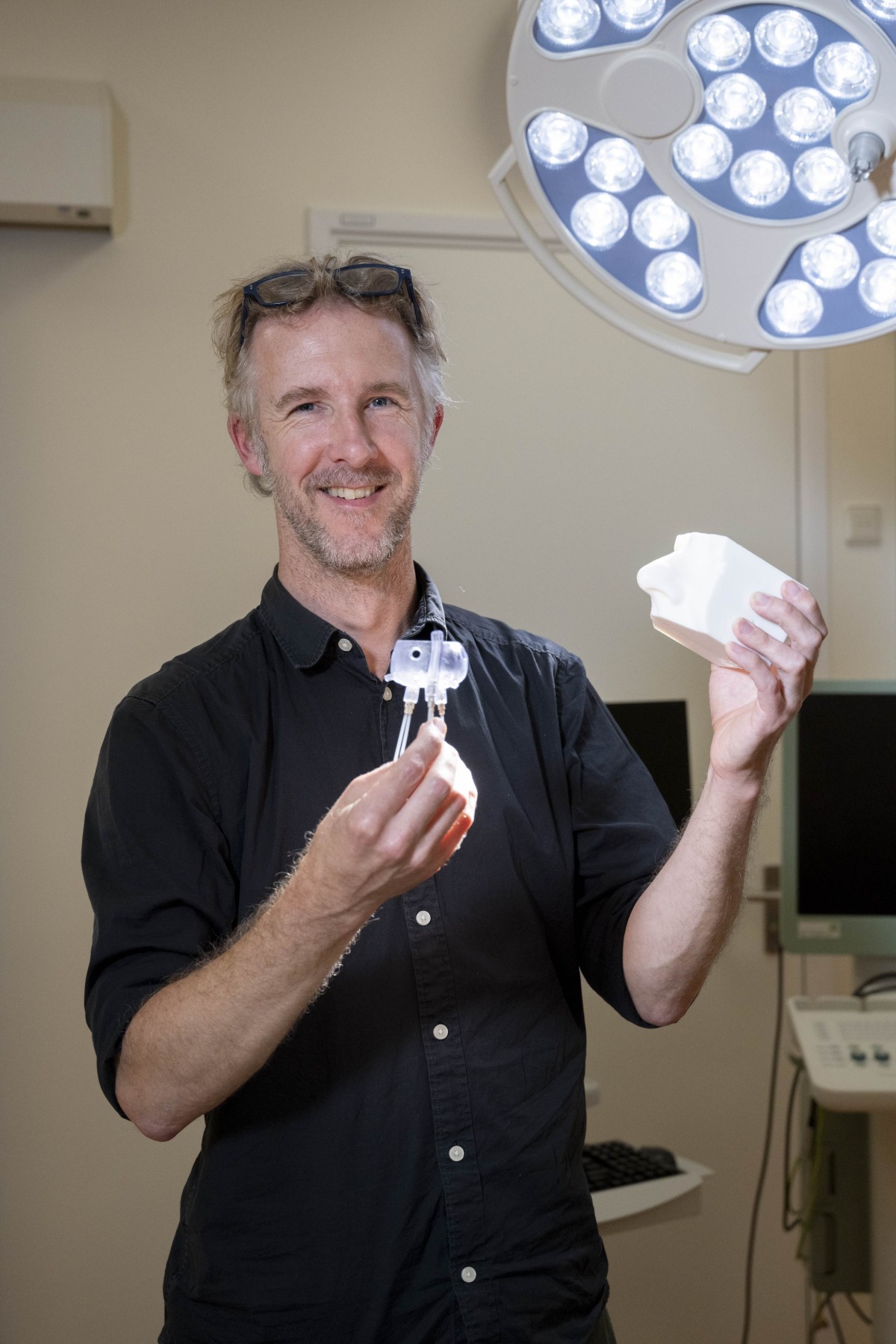

Maarten Kastelijns

Designing the mold is the job of Maarten Kastelijns, a radiation therapy technician at UMC Utrecht. He specializes in designing 3D prints for brachytherapy. “Based on medical imaging, together we make a plan to place the tubes as close to the tumor as possible. The technicians then design a mold around it using a type of plastic.” This mold consists of a base that fits around the patient’s nose and has various components. “There are attachment holes to secure the mold to the nose, and a mechanism that allows us to attach the tubes to the mold.”

For practitioners to administer the optimal amount of radiation, the mold remains in place during treatment. This can be uncomfortable for the patient. “Thanks to the mold, the treatment plan is guaranteed,” says Kastelijns. “Punching the holes and attaching the mold can be painful. That’s why we do it under anesthesia. Once the patient is awake, the pain is usually not too bad. Paracetamol is often enough to complete the treatment.”

Because the mold remains in place, many patients experience nasal congestion, says De Ridder. “They feel like they have a cold for a week. You can’t blow your nose with the mold in place, so we printed holes in it to administer nasal spray. That way, they can still clear their nose.” When the mold is removed after the treatment, it often feels like a relief. “The mucus and phlegm find their way out when patients can suddenly breathe through their nose again.”

Then the recovery process can begin. “Removing the stitches is quick and easy and is similar to removing an IV. We do that in the treatment room, without anesthesia,” says De Ridder. In the following period, the nose reacts to the radiation treatment. “That’s often an unpleasant period, because people get scabs in their nose that start to bleed quickly. But after about six weeks, the tumor has disappeared and the inside of the nose has healed.”

3D molds and some components

Thanks to the positive results, the researchers see opportunities to use molds for other tumors that are not currently treated with brachytherapy, such as sinus cancer. “We never had suitable molds for that type of treatment,” says Kastelijns. “Now that we are able to make them ourselves, that may change. Depending on the shape and application, we can even vary the material to be printed. We don’t yet know what the best method is for each indication, but we see many applications in the future, especially in the head and neck area.”

“Brachytherapy provides a much more even dose distribution, sparing so much more tissue than other techniques,” says De Ridder. “We have been treating a dozen patients for years, but with the addition of the molds and the results they produce, we are seeing that number rise. If we can perfect this technique even further, it would be a welcome addition for the patient.”