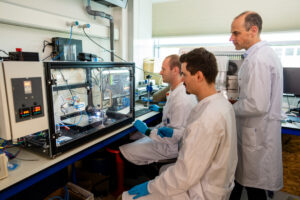

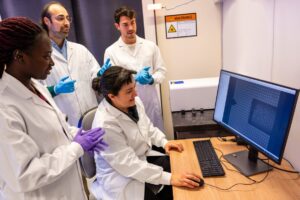

Team members of the Biofabrication Facility Utrecht in the lab:

Maldalab colleagues

Colleagues of the levatolab.eu

Below an overview of the bioprinting and prototyping techniques:

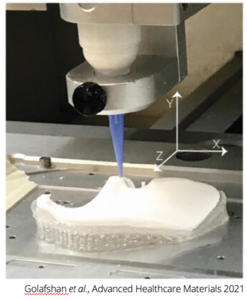

Extrusion-based bioprinting (EBBP) systems are the most widely used bioprinting methods to date given their highly diverse set-ups and commercial brands, and their compatibility with a myriad of biocompatible materials like hydrogels, ceramics, thermoplastics and other composite materials.

With EBBP it is possible to directly dispense cells in a predefined structure/pattern. Most systems employ either air pressure- or piston-based extrusion systems to controllably deposit filaments of material onto a collector surface, to build 3D objects in a layer-by-layer fashion. The technique can be adapted to incorporate multiple materials in different printing cartridges with temperature control, is compatible with living cells and can be employed with a wide variety of nozzles, and even within support baths to achieve greater design freedom.

By utilizing extrusion (bio)printers, researchers and scientists can develop innovative solutions for tissue engineering, regenerative medicine, and biomedical research.

Output examples:

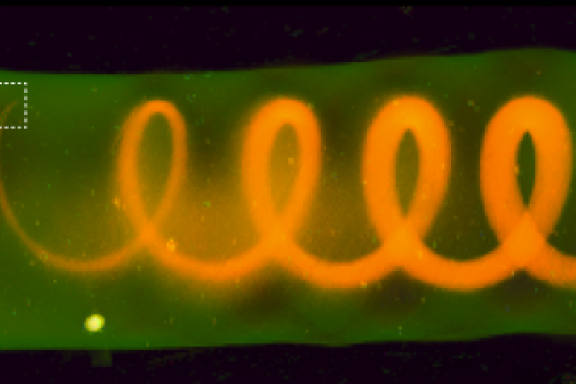

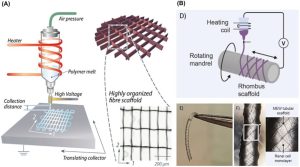

Melt Electrowriting (MEW) is a type of additive manufacturing technique that uses a combination of heat and electrostatic forces to deposit molten polymer fibers onto a substrate. A polymer is extruded through a nozzle and accelerated by applying a high voltage to the material. With this acceleration, fiber diameters down to 1 um are possible. Allowing the creation of high-resolution constructs, with mechanical structure. MEW is particularly well-suited for thermoplastic materials. MEW can be applied for planar, non-planar, and tubular printing.

Working with the MEW printer:

Output example:

From:

Daghrery A, de Souza Araújo IJ, Castilho M, Malda J, Bottino MC. Unveiling the potential of melt electrowriting in regenerative dental medicine. Acta Biomater. 2023 Jan 15;156:88-109. doi: 10.1016/j.actbio.2022.01.010. Epub 2022 Jan 10. PMID: 35026478; PMCID: PMC11046422.

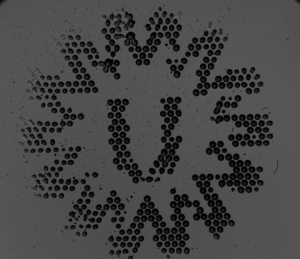

The Next Generation Bioprinter – Research (NGB-R, from Poietis) is a cutting-edge bioprinter that combines Laser Induced Forward Transfer (LIFT) technology with extrusion bioprinting. Equipped with a 6-axis robotic arm and a bright field microscope, this device enables precise and accurate printing of biomaterials. The LIFT technology uses a high-powered laser to create micrometer-sized droplets, allowing for high-resolution micropatterning and 2.5D printing. This bioprinter is particularly suited for cell-laden experiments, with high viability rates of up to 97%, and enables the printing of single cells, spheroids, and organoids. With its advanced features and capabilities, the NGB-R is an ideal tool for researchers and scientists working in the field of bioprinting and regenerative medicine.

Output example:

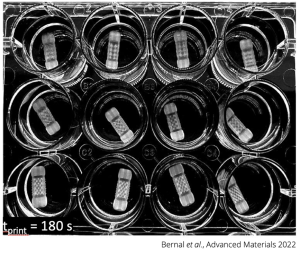

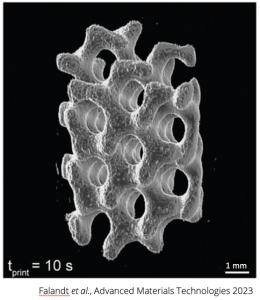

Volumetric bioprinting is a tomography-inspired, light-based bioprinting approach capable of fabricating centimeter-scale, cell-laden constructs in tens of seconds. This technique can achieve high levels of print complexity given its one-step printing approach, which is accomplished though the creation of a 3D dose distribution throughout a vial of photosensitive bioresin, where only regions where enough light accumulates photocrosslink into the desired object. The fast and contactless nature of this approach, as well as the use of visible light sources (several laser wavelengths available) make the technique compatible with sensitive cell types and larger biological units such as dense cell aggregates and organoids. The machine is compatible with a wide range of photosensitive materials, from biocompatible hydrogels to acrylates and epoxy resins, and can be converged with various other AM techniques (see extrusion-based bioprinting and melt electrowriting).

Output examples:

Fused Deposition Modeling (FDM) is a type of 3D printing technology that uses melted polymer filament to create three-dimensional objects. This additive manufacturing technique enables users to rapidly produce functional prototypes and test their designs, making it an ideal tool for various research and development applications. With its speed and versatility, FDM is particularly useful for printing custom holders or fixtures for experiments, as well as for engineering-related research and development. By leveraging FDM, users can quickly create and test prototypes, accelerating the product development process and reducing costs.

Fused Deposition Modeling (FDM) is a type of 3D printing technology that uses melted polymer filament to create three-dimensional objects. This additive manufacturing technique enables users to rapidly produce functional prototypes and test their designs, making it an ideal tool for various research and development applications. With its speed and versatility, FDM is particularly useful for printing custom holders or fixtures for experiments, as well as for engineering-related research and development. By leveraging FDM, users can quickly create and test prototypes, accelerating the product development process and reducing costs.

From: Meerbothe T, Florczak S, van den Berg C, Levato R, Mandija S. A reusable 3D printed brain-like phantom for benchmarking electrical properties tomography reconstructions. Magnetic Resonance in Medicine. doi: 10.1002/mrm.30189

From: Meerbothe T, Florczak S, van den Berg C, Levato R, Mandija S. A reusable 3D printed brain-like phantom for benchmarking electrical properties tomography reconstructions. Magnetic Resonance in Medicine. doi: 10.1002/mrm.30189

Overview 3D printers

The Stereolithography (SLA) and Digital Light Processing (DLP) printers are types of 3D printing technology that uses a light to solidify liquid resin (photopolymerization, VPP), creating highly detailed and accurate structures. This technology enables the fabrication of complex shapes and geometries, making it an ideal tool for various (bio)engineering projects and experiments.

The Stereolithography (SLA) and Digital Light Processing (DLP) printers are types of 3D printing technology that uses a light to solidify liquid resin (photopolymerization, VPP), creating highly detailed and accurate structures. This technology enables the fabrication of complex shapes and geometries, making it an ideal tool for various (bio)engineering projects and experiments.

With its high resolution and accuracy, the VPP printers are particularly suited for applications such as tissue engineering, microfluidics, and biomedical research.

By utilizing the VPP printers, researchers and engineers can produce complex models and prototypes with unprecedented precision and detail.

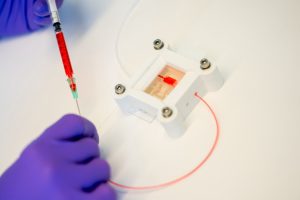

Example of a finalized prototype, using FDM and VPP printings for organ-on-chip design: